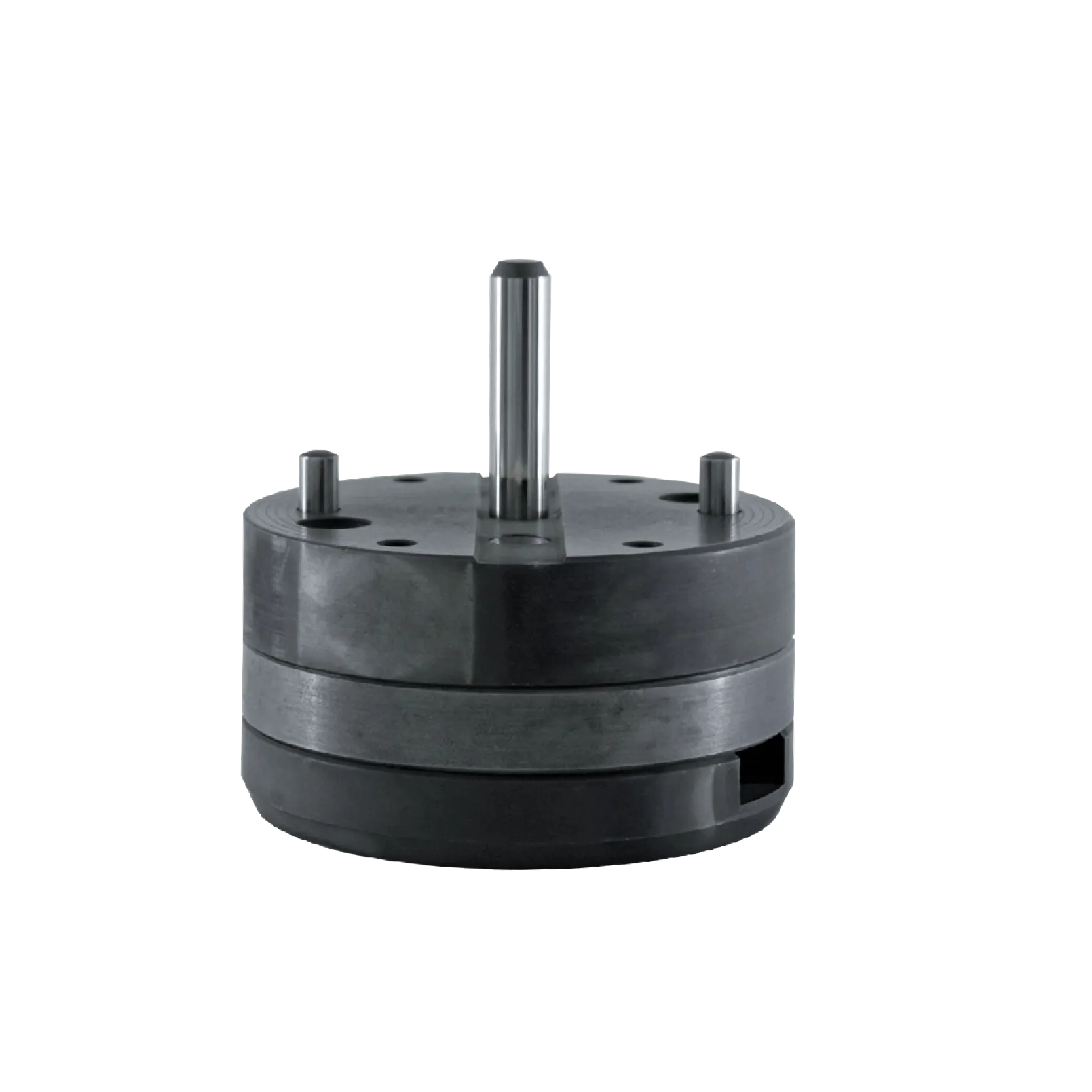

Gear pump

Maintenance-friendly and economical

Gear pumps have a long history in our temperature control units. Over decades, the gear pump has been continuously developed and so there are now three different variants of it. The gear pump consists of three pump plates and a set of gears that are screwed together without seals. Precisely because of this simplicity in maintenance and servicing and the resulting extremely high economic efficiency, the gear pump enjoys a high reputation among our customers. The gear pump is currently produced in the variants 16l, 30l and as a double pump 2 x 16l. Due to the very steep characteristic curve, our gear pump is also suitable for a permanent supply of mold channels up to 4 mm in diameter. The design also allows the gear pump to be operated permanently up to 350 °C in leak-stop mode, whereby it can also be used to suck the heat transfer medium out of the mold.

Gear pump 16l

- Application: Immersion pump in temperature control unit

- Max. 16 l/min flow rate

- Max. 160 m delivery head

- Conveying medium: Heat transfer oil and water/glycol

Gear pump 30l

- Application: Immersion pump in temperature control unit

- Max. 30 l/min flow rate

- Max. 130 m delivery head

- Conveying medium: Heat transfer oil and water/glycol

Double pump 2 x 16l

- Application: Immersion pump in temperature control unit

- Max. 2 x 16 l/min flow rate

- Max. 130 m delivery head

- Conveying medium: Heat transfer oil and water/glycol

Accessories for temperature control units

Maintenance accessories

Flow meters and descaling pumps ensure optimal operation.

Connection accessories

Thermal hoses, pipe assemblies, and connection fittings.

Heat transfer oils

Our Thermobiehl 500 and 700 heat transfer oils for optimal performance and efficiency.

Other accessories

Neutralization lye, descaler, corrosion protection agents, and mold cleaners.