swift

Single-circuit

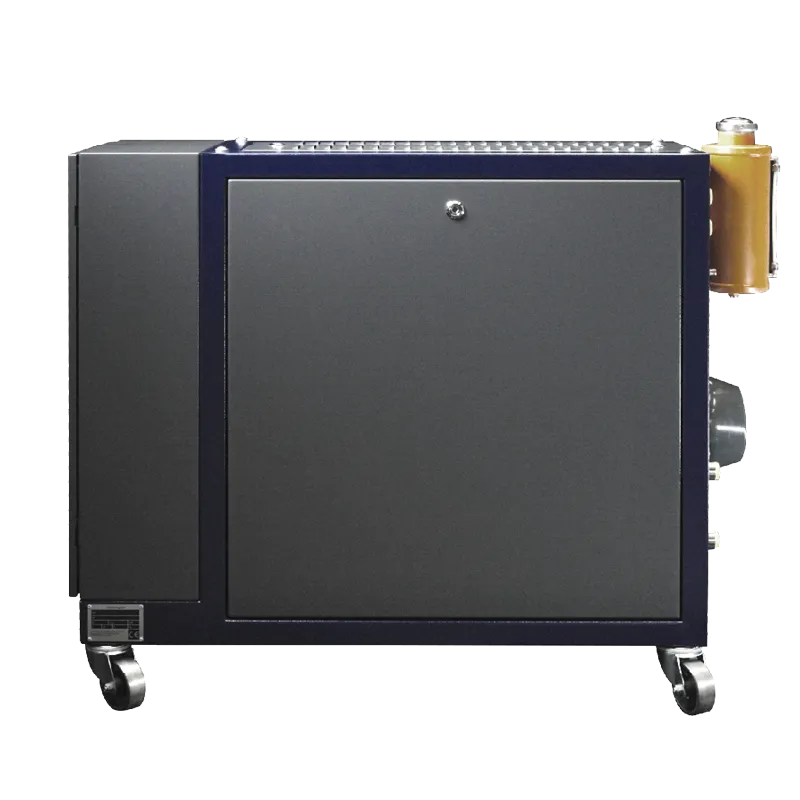

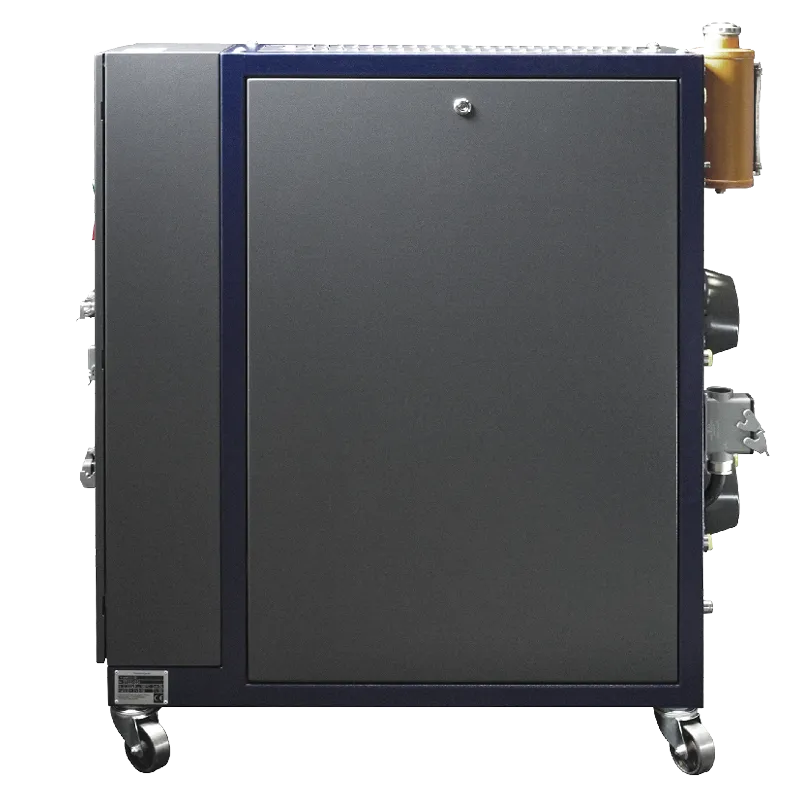

swift one

Our swift series as a single-circuit version offers a powerful and highly efficient temperature control unit for temperature control of consumers in the temperature range from 20 °C to 180 °C.

With its robust and compact design and at the same time good accessibility for maintenance work, our temperature control units can be used in a wide variety of production environments.

Temperature range

20 to 180 °C

Tempering circuits

1

Control unit

woodpecker / sparrow

Pump type

46 l/min 7 bar

58 l/min 10 bar

A highlight of the temperature control unit is our peripheral impeller pump in combination with the drive unit.

Peripheral impeller pump

Thanks to high-quality materials and a well-thought-out design, the pump is extremely resistant to industrial water and convinces with its durability.

Highest quality.

Avoid costly bad purchases!

The importance of the right—energy-efficient—connection for the performance of a temperature control unit is often underestimated. Only those who optimally coordinate their equipment and infrastructure can achieve maximum efficiency.

Features

Function & Performance

- Space-saving design

- Pressure relief on emergency stop

- Flow measurement via temperature difference

- Self-optimizing control unit

- High cooling capacity

- Decalcification function cooling circuit

- Working and operating hours counter

- Easy accessibility for service and maintenance work

Safety & Monitoring

- Safety temperature limiter with shutdown

- Pressure safety valve

- Leakage detection

- Energy saving option

- Dry run protection

- Energy saving motor

- Weekly timer

- Level monitoring

Additional standard equipment

In addition to the normal standard equipment of a temperature control unit, our temperature control units offer further equipment features as standard.

- Interface RS 485

- Control optionally via flow or return

- Collective alarm via LED

- External connection heating/operation

Optional

In addition to the different interface designs or flow measurement, a corrosion protection system can be installed in our temperature control units. This adds the corrosion protection agent to the temperature control system on a percentage basis. The percentage is variably adjustable and can be adapted to the respective water quality in the company. Thus, sufficient corrosion protection is always guaranteed.

- Interface Profibus

- Interface Profinet

- Flow measurement

- Variable corrosion protection system

Product data

- Tempering circuits: 1

- Control unit: woodpecker / sparrow

- Max. flow temperature: 160 °C / 180 °C

- Circulating water volume: 6.2 l

- Heating capacity per circuit: 12 / 18 / 24 kW

- Cooling capacity per circuit: 120 kW

- Flow rate per circuit: 46 / 58 l/min

- Power consumption motor: 0.55 / 1.1 kW

- Max. pump pressure: 7 / 10 bar

- Connection voltage: 400V / 440V

- Connection system and water circuit: IG ½”

- Weight: 125 kg

- Dimensions W/H/D: (350/890/1100) mm

Accessories for temperature control units

Maintenance accessories

Flow meters and descaling pumps ensure optimal operation.

Connection accessories

Thermal hoses, pipe assemblies, and connection fittings.

Heat transfer oils

Our Thermobiehl 500 and 700 heat transfer oils for optimal performance and efficiency.

Other accessories

Neutralization lye, descaler, corrosion protection agents, and mold cleaners.