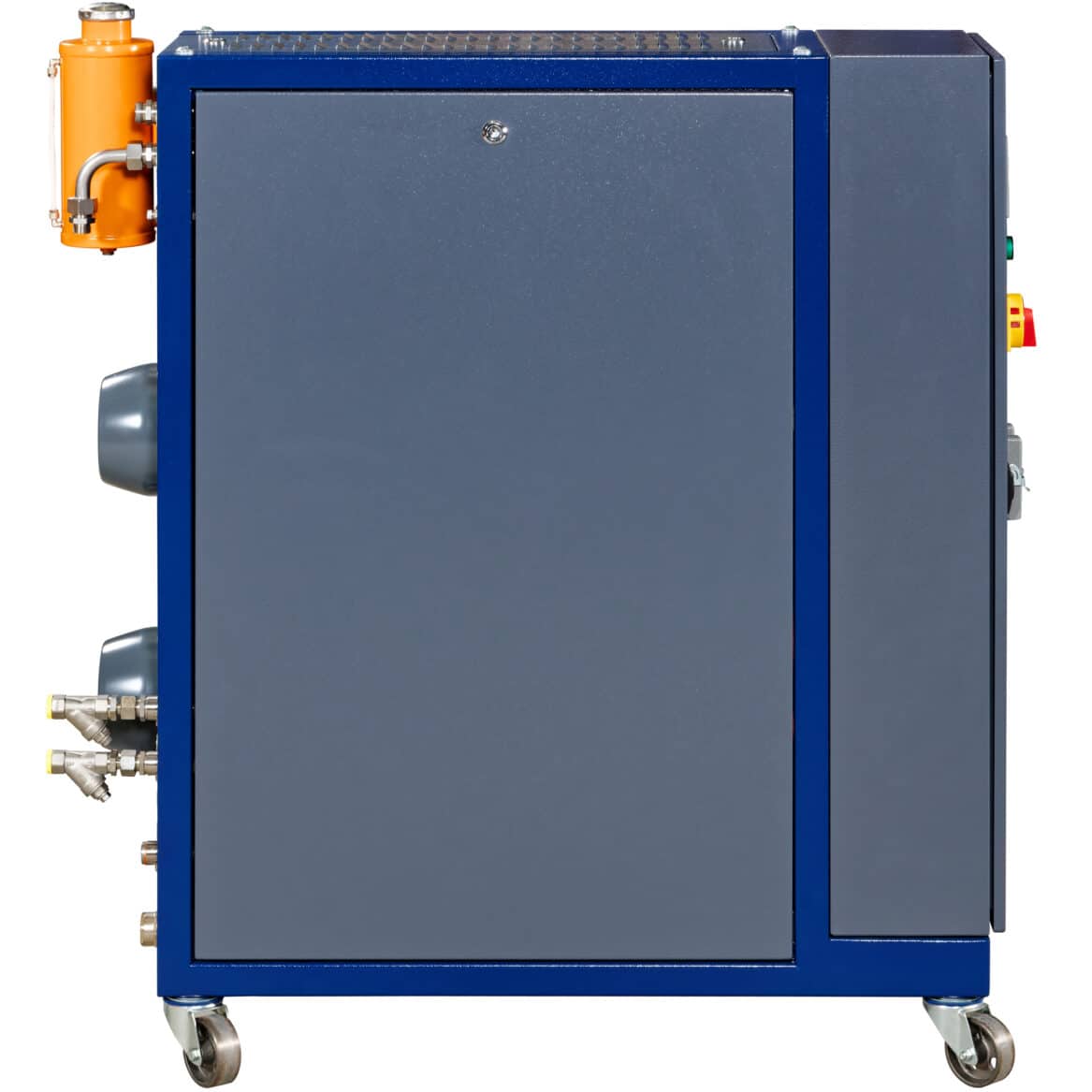

swift

Temperature regulation circuits

2

Temperature regulation circuits

20 to 180 °C

Control unit

woodpecker

Equipment variant

Additional cooler

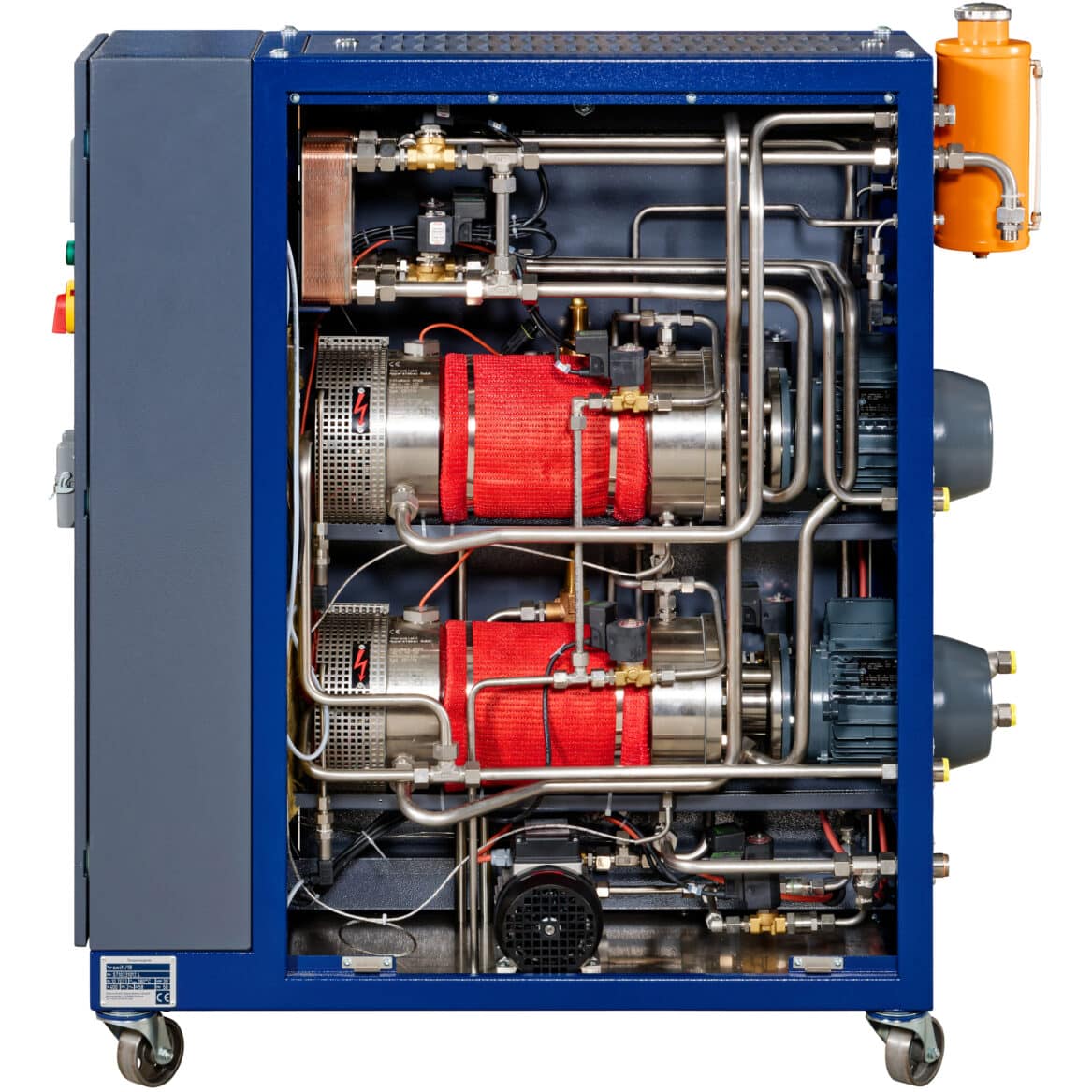

Product features

Compact, maintenance-friendly design

Additional cooler

Safety temperature limiter with limit switch

Flow monitoring

Self-optimising control unit

Leakage detection

Energy-saving option/energy-saving motor

High cooling capacity

Dry-running protection

Energy-saving motor

Performance-optimised filling pump

Descaling function - cooling system

Weekly timer

Fill level monitoring

Are you interested in rental equipment?

Downloads

Product data

swift

At temperatures above 100°C, there is a physical increase in pressure within the closed temperature control system. This can pose a risk to the operator if handled incorrectly. Our temperature control units therefore offer comprehensive safety functions including warning information to protect the operator from potential hazards.

- Software-supported safety shutdown

- Permanent tank pressure monitoring

- Pressure safety valve

- Automatic pressure relief in the event of an emergency stop

- Safety temperature limiter with limit switch

In addition to the normal standard equipment of a temperature control unit, our temperature control units also offer other standard features.

- RS 485 interface

- Can be controlled either via the feed or return line

- Collective error message via LED

- External connection for heating/operation

In addition to the various interface versions or the flow measurement, a corrosion protection system can be installed in our temperature control units. This is used to add the rust inhibitor to the temperature control system as a percentage. The percentage is variably adjustable and can be adapted to the respective water quality in the company. This ensures adequate corrosion protection at all times.

- Profibus interface

- Profinet interface

- Flow measurement

- Variable corrosion protection system

- Core breakage monitoring

Accessories for temperature control units

Accessories for temperature control units

Service products

Connection accessories

Heat transfer oils