Cleaning device

Merlin

With our Merlin cleaning device, we can easily remove stubborn impurities such as limescale, corrosion residues, oil or metal shavings from temperature control channels and supply lines. Impurities have an insulating effect, so regular cleaning ensures the best possible heat transfer within the temperature control channel.

Impurities in the temperature control channels and supply lines reduce the heat exchange between the heat transfer medium and the consumer. The term impurities may include limescale, corrosion residue, cracked oil, blasting material or metal shavings, for example. These residues can have a major impact on product quality and cycle times and, in the worst case, damage the temperature control unit's conveyor unit.

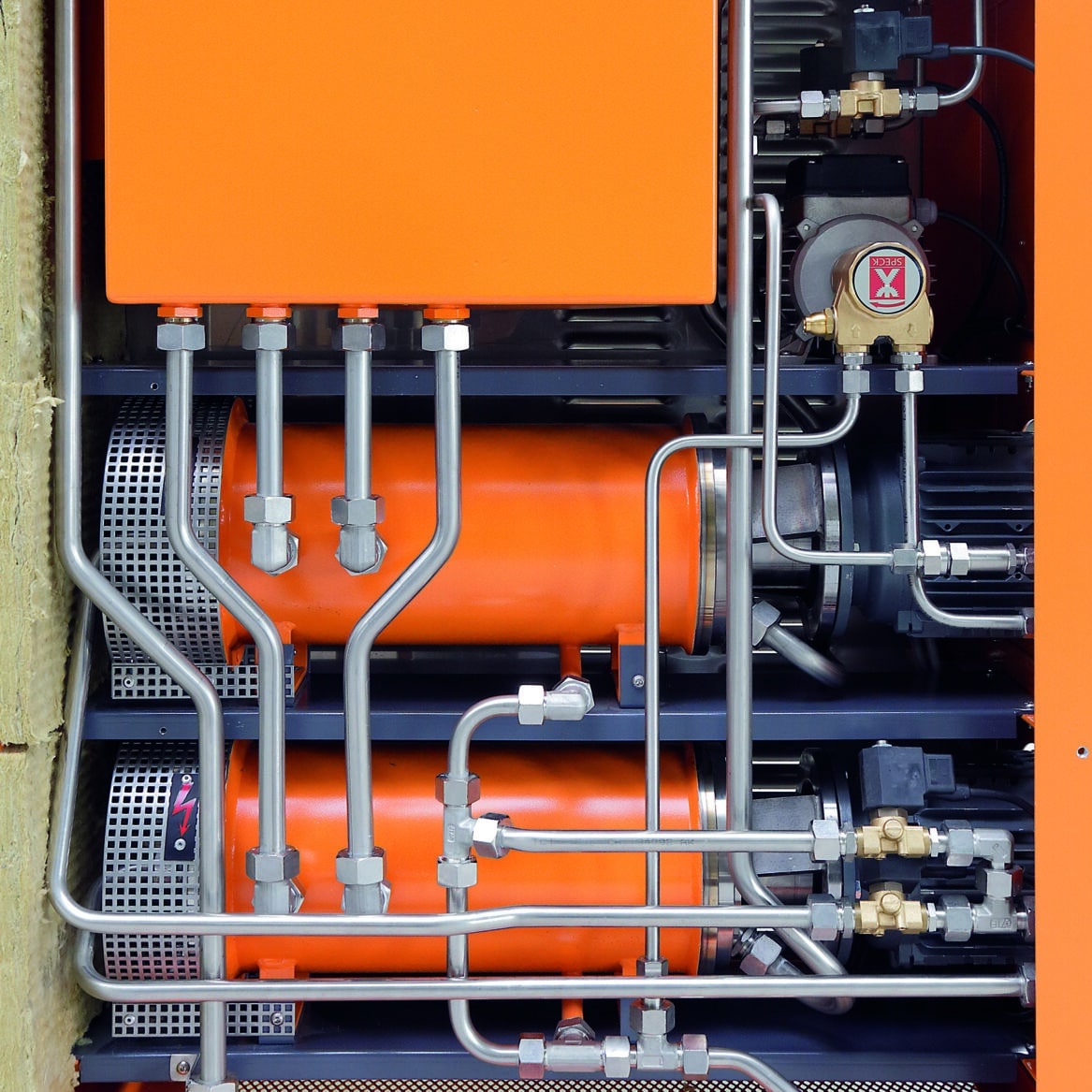

This is exactly where our Merlin cleaning device comes in. Thanks to its compact design, it can be used directly on the machine in place of a temperature control unit. The temperature control channel is cleaned with a predetermined mix of cleaning fluid and tempered water. The Merlin cleaning device works without pressure with an open system and separates a wide variety of soiling and removes them from the circuit. After the cleaning process, the flow rate and therefore the effectiveness of the cleaning process can be checked. By pressurising the temperature control channel, leaks can be detected at an early stage and rectified by the operator. The cleaned temperature control channel is then evacuated and a temperature control unit can be reconnected and put back into operation.

Product features

Leakage check

Suction function

Evacuation function

Flow check

Automatic flow reversal

Compact design

Automatic filling

Stainless steel design

Are you interested in rental equipment?

If you have any questions about rental equipment or need advice, please contact us. We will be happy to help you.

Accessories for temperature control units

Accessories for temperature control units

Service products

Flowmeters and decalcification pumps keep processes running smoothly.

Connection accessories

Thermal tubes, pipes and connection fittings.

Heat transfer oils

Our heat transfer oils thermobiehl 500 and 700 ensure optimum performance and efficiency.

Other accessories

Neutralising lye, descaler, rust inhibitor and casting mould cleaner.